Exploring Virtual Reality in Manufacturing: A Comprehensive Guide

The manufacturing landscape is undergoing a metamorphosis. Legacy methods are giving way to innovative technologies, and Virtual Reality (VR) stands poised as a revolutionary force. At SMACAR, a pioneering leader in virtual and 360° video production, we understand the unique challenges faced by manufacturers. We leverage our expertise in user-friendly, state-of-the-art VR interfaces to tailor solutions that meet your specific needs.

The integration of Virtual Reality (VR) technology is rapidly reshaping the manufacturing sector. As industries strive to enhance precision, efficiency, and safety, VR emerges as a transformative tool. This guide delves into how VR is revolutionizing traditional manufacturing methods, introducing innovations that optimize production and elevate training to new heights.

The VR Advantage in Manufacturing

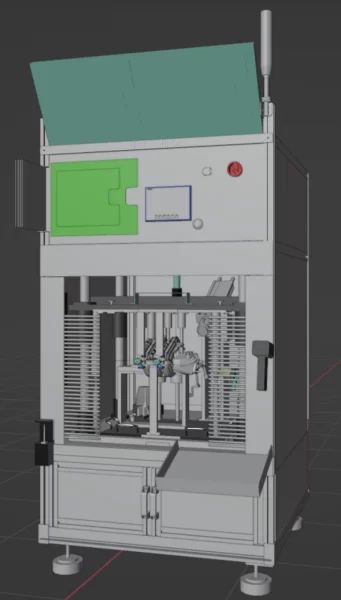

VR technology offers immersive experiences crucial for the advancement of manufacturing processes. By creating virtual replicas of environments, manufacturers can experiment with plant layouts and system configurations in a cost-effective, risk-free setting. This ability not only accelerates decision-making but also significantly reduces the financial burden associated with physical trials.

Key Applications of VR in Manufacturing

1. Design and Prototyping

- Innovative Design with VR: VR allows manufacturers to visualize product designs in detailed three-dimensional spaces. This capacity for detailed visualization helps in refining product specifications before the commencement of physical production, ensuring that potential issues are addressed early in the design phase.

- Enhanced Collaboration: VR facilitates unprecedented collaboration across continents, allowing design and engineering teams to work together in real-time within the virtual space. This synchronicity drastically reduces development cycles and fosters a more dynamic approach to innovation.

2. Training and Safety

- Simulation-Based Training: VR transforms the training landscape by providing realistic, interactive simulations where employees can learn and refine their skills without the physical risks typically associated with manufacturing training. These simulations can replicate everything from routine operations to complex machinery handling.

- Emergency Preparedness: VR is instrumental in training staff for emergency scenarios, including equipment failures and safety protocol breaches. Through realistic simulations, employees can practice their response to various crises, ensuring readiness and potentially saving lives.

3. Enhanced Production and Quality Control

- Virtual Production Lines: Manufacturers use VR to simulate and analyze production processes. This virtual analysis helps identify inefficiencies and test potential adjustments without interrupting ongoing operations, leading to smoother production flows and enhanced throughput.

- Quality Assurance: By implementing VR in quality control, manufacturers can conduct thorough inspections and detect defects early. This proactive approach ensures the production of high-quality goods and maintains compliance with industry standards.

4. Client Engagement and Sales

- Virtual Factory Tours: VR technology enables manufacturers to offer virtual tours of their facilities, providing transparency and strengthening trust with clients and stakeholders. These tours are especially beneficial for remote or international customers who cannot visit the plant in person.

- Customization and Configuration: Through VR, clients can customize products in a virtual environment, selecting materials, colors, and designs in real-time. This interactive process not only enhances client satisfaction but also streamlines the customization process for manufacturers.

5. Future Trends in VR Manufacturing

- Integration with IoT and AI: The convergence of VR with other technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) is paving the way for smarter, more interconnected manufacturing environments. This integration promises enhanced data collection and analysis, leading to better decision-making and predictive maintenance.

- Advanced Training Capabilities: Future VR training modules will likely offer adaptive learning environments that tailor educational content based on individual performance, enhancing the effectiveness of training programs and accelerating competency development.

SMACAR: Your VR Manufacturing Partner

Imagine a world where:

- Prototyping is rapid and cost-effective.

- Employee training is engaging and immersive.

- Design visualization is clear and collaborative.

- Production workflows are optimized and error-free.

This is the transformative power of VR in manufacturing – a power SMACAR can help you harness. Our VR manufacturing solutions empower you to achieve:

- Reduced Costs: Streamline prototyping, minimize waste, and optimize processes with VR.

- Enhanced Efficiency: Improve production workflows, reduce errors, and ensure quality control.

- Increased Productivity: Empower your workforce with engaging VR training and skill development.

- Faster Time to Market: Accelerate design cycles and bring innovative products to market quicker.

- Improved Design Collaboration: Facilitate better communication and collaboration across design teams.

VR Manufacturing: A Game-Changer Across Industries

Traditional manufacturing relies on static 2D blueprints and cumbersome physical prototypes. These methods can be time-consuming, expensive, and prone to errors. VR offers a revolutionary alternative, creating a dynamic, immersive environment where manufacturers can:

- Visualize complex designs: Explore intricate product components in 3D, allowing for better design decision-making.

- Conduct rapid prototyping: Design, iterate, and test virtual prototypes before committing to physical models, saving time and resources.

- Train employees in a safe environment: Immerse employees in realistic VR simulations to practice complex procedures, improve skill development, and enhance safety awareness.

VR Manufacturing Training: Your Workforce, Empowered

A skilled workforce is the backbone of any successful manufacturing operation. However, traditional training methods can be laborious and ineffective. VR training offers a solution, providing employees with an engaging and immersive learning experience that:

- Increases knowledge retention: Interactive VR simulations enhance learning and information absorption compared to traditional methods.

- Improves skill development: Employees can practice real-world tasks and scenarios in a safe virtual environment.

- Reduces training time: VR training simulations can significantly accelerate the training process, leading to faster onboarding and upskilling.

VR in Manufacturing: Real-World Applications Across Industries

SMACAR’s VR manufacturing solutions cater to a diverse range of applications across various industry segments. Here are some compelling examples:

- Automotive Manufacturing: Virtually test drive prototypes, explore complex engine designs, and train technicians on assembly and maintenance procedures.

- Aerospace Manufacturing: Design and visualize intricate aircraft components, simulate flight procedures for test pilots, and train maintenance crews on complex systems.

- Medical Device Manufacturing: Design, prototype, and test medical devices in a virtual environment, ensuring safety and functionality before production.

- Consumer Goods Manufacturing: Explore product designs in 3D, create engaging virtual showrooms for customer demonstrations, and train on efficient assembly processes.

Case Study : Mahle

We used state-of-the-art VR technologies to enhance Mahle Anand Filters India Private Limited’s employee training. Yaksha increased employee confidence and operational efficiency by reducing training durations and minimizing errors through the use of augmented reality guides and virtual reality training floors. This marked a significant advancement in technical training for manufacturing, as these creative solutions not only streamlined Mahle’s training procedures but also freed up senior staff to concentrate on core development activities. This project demonstrates how we can use cutting-edge technology to improve manufacturing and automotive industry procedures. Yaksha also helped to do this project. Yaksha is an AR VR Company in India.

Conclusion

The ongoing evolution of VR technology holds remarkable potential to further revolutionize the manufacturing industry. By embracing VR, manufacturers are not only enhancing their design and production processes but are also setting new standards in training and operational efficiency. As VR technology continues to advance, its role in manufacturing is set to grow, promising a future where digital transformation drives industry-wide innovation and sustainability.